SK Innovation to Use PolyPlus’ Glass Separator Tech for Li Battery Development

Polish company, SK Innovation reported that it signed a joint development agreement to develop Li metal batteries with PolyPlus Battery Company, a U.S. battery technology development firm on February 18, in Berkeley, California The technology was acquired as part of SK Innovation's strategy to aggressively secure future core technologies.

Under this agreement, SK Innovation will invest in research and development of conductive glass separators owned by PolyPlus. The company said it is also considering options of making an equity investment in the U.S. company and licensing its technology in the future.

The battery technology of PolyPlus features anodes with glass-protected solid-state lithium anode laminate that PolyPlus says doubles the energy density of current rechargeable batteries. The technology for the novel anode coating allows integration into existing battery designs.

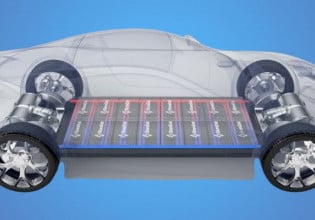

However, the technology that SK Innovation will license from PolyPlus is the related technology for glass separators. (see image above). PolyPlus recognized that thin continuous monolithic glass sheets have sufficient flexibility and conductance for the application. Continuous monolithic glass sheet acts as a barrier to dendrites and facilitates efficient Li cycling.

SK Innovation plans to complete research on conductive glass separators by the end of 2021 and apply it to developing lithium anodes for lithium metal batteries.

According to PolyPlus Battery, a lithium metal battery with a lithium anode has a capacity more than 10 times that of graphite anode, so its energy density is about 1000Wh/L, almost twice that of a conventional lithium-ion battery, making it one of the battery models for future electric vehicles.

However, there is also a limitation. During charging, lithium dendrites (twig-shaped crystals that grow abnormally on the metal surface) are formed on the surface of typical anodes, which penetrate and damage the separator, eventually causing a fire.

For this reason, SK Innovation and PolyPlus Battery both consider that the conductive glass separator to be an essential material for the commercializing Li metal batteries because it can stabilize the battery by preventing dendrites from breaking through the separator.

The deal marked the first case in which SK Innovation secured a new technology through the open innovation approach launched by the Institute of Technology Innovation at SK Innovation last year. Open innovation refers to a way of acquiring technologies through collaboration with external experts, including forming consortiums with other companies, universities, or research institutes. SK Innovation says such technology acquisitions can effectively reduce uncertainties in investing in future technologies.

Open innovation is advantageous in that it can minimize risks through fast decision making and accelerate development through cooperation with technology-holding firms. As companies can secure technologies in a timely manner by reflecting rapidly evolving technology development trends, open innovation is mostly used in biopharmaceutical and environment-friendly materials industries.

SK Innovation has established a research and development cooperation ecosystem by networking with major research institutes and universities in the U.S. and Europe since 2017. The company plans to continuously expand it into a business cooperation ecosystem through collaborative projects like this investment agreement. In addition, SK Innovation is preparing other research and development cooperation projects for battery metal recycling and development of eco-friendly materials.

Lee Sung-joon, head of the Institute of Technology Innovation at SK Innovation, said, "In the fast-paced battery business for electric vehicles, the core next-generation competence is technological prowess. We will continue to expand cooperation with various outside organizations by utilizing open innovation."

Beginning last year, SK Innovation decided to invest heavily in its battery business and is building battery production facilities in Changzhou in China, Komarom in Hungary, and Georgia in the U.S. as well as in Korea. The company intends to increase its total production to 60GWh by 2025 by securing additional orders.