IC Process with Ultra-High Breakdown Voltage for Digital Isolators

MagnaChip Semiconductor Corporation today announced it now offers a multi-level thick IMD (Inter-Metal Dielectric) process for a capacitor with ultra-high breakdown voltage. This capacitor is useful for the digital isolation and capacitive coupling in electronic circuits.

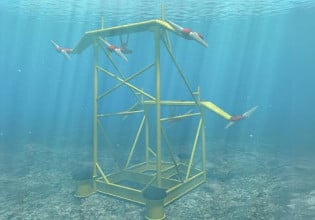

Demand for digital isolators is growing for noise-immune electronics products commonly found in electric vehicles and in industrial, communications and healthcare applications as a substitute for conventional optocouplers.

Digital isolators demonstrate superior performance and reliability and can achieve higher levels of integration at lower cost, as compared to optocouplers. Industry analyst expects the worldwide digital isolator market will reach approximately $2 billion by 2023 at a CAGR (Compound Annual Growth Rate) of six percent between 2017 and 2023.

MagnaChip's multi-level thick IMD process consists of back-end-of-line process module including IMD with a thickness from 5um to 6um per metal layer. Depending on the breakdown and capacitance requirements, the thick IMD can be stacked together up to three layers to allow the design of the metal-insulator-metal capacitor with insulator thickness in the range of 5um to 20um.

This capacitor will withstand from about 4kV to 15kV before breakdown, which is suitable for capacitive isolation of a digital signal from ultra-high voltage noise from outside environments.

The multi-level thick IMD process module, which has already passed the reliability requirements for automotive AEC Q-100, is now integrated into MagnaChip's 0.18um BCD and Mixed Signal process technologies. The Process Design Kit is available to support on-chip integration.

YJ Kim, MagnaChip's Chief Executive Officer, commented "We are very pleased to provide a special multi-level thick IMD process for ever-growing capacitive isolation applications. This is a significant addition to our many specialty process technologies." Mr. Kim added, "We will continue to provide innovative and differentiated technologies to meet the fast-changing needs of our foundry customers."