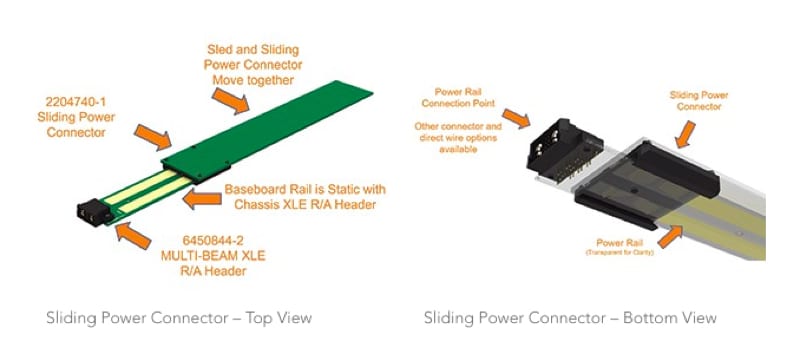

75A Sliding Power Connector Hot-Swappable in Server Drawers

TE Connectivity (TE) has introduced a sliding power connector that the company says is one of the only hot-swappable (serviceable) connectors of it's kind in a server drawer without shutting power down to the entire system. The sliding power connector can reduce the need for system downtime that is normally required when swapping server drawer components, thereby saving significant operational costs.

The company designed the sliding power connector for applications such as hard disk drives, power supply units, racks, servers, storage units, and other high-current applications.

The sliding power connector can minimize the need for a bulky cable management system within the drawer, opening up more space for airflow and reducing overall cooling costs.

Due to a more direct path from the power source to the server, it shows improved voltage drop over cables, increasing energy efficiency. With limited cabled connections, TE Connectivity contends that the sliding connector is more reliable than a conventional connector. A Simpler design makes it less prone to disconnection from the power source. No complex cable management or loose moving parts within the drawer are required.

The connector utilizes PCBs to transmit power directly to the on-board components, potentially eliminating the need for power cables. Increased airflow reduces cooling costs.

"Key server system components can fail, and when they do, IT professionals need a way to swap in new components quickly and efficiently," said Amy Wilson, product manager in TE Connectivity's data and devices business unit. "TE's sliding power connector addresses this requirement by minimizing the need for powering down the server during component replacement operations."

WHAT IS SLIDING POWER?

Non-traditional method of power distribution

- Connector system that can eliminate the need for power cables

- Utlizes PCBs to transmit power directly to the on-board components

No system downtime

- Allows for hot swapping of components without shutting power down to the whole system

Energy efficient

- Increased airflow reduces cooling costs

- Improved voltage drop due to a more direct path from the power source to the server

Higher reliability

- No complex cable management or loose moving parts within the drawer

- Simple design is less prone to disconnection from the power source