24M Partner Kyocera to Validate Process for Thick-Electrode Li-Ion Battery Volume Production

24M reported that investor and long-time partner, Kyocera, will install capacity to validate the unique 24M SemiSolid manufacturing platform. The facility, which is under construction in Osaka, Japan, will support pilot production of residential solar + storage systems in the Japanese market.

24M claims that its SemiSolid manufacturing platform delivers a significant structural bill of materials advantage and requires considerably less capital investment up front.

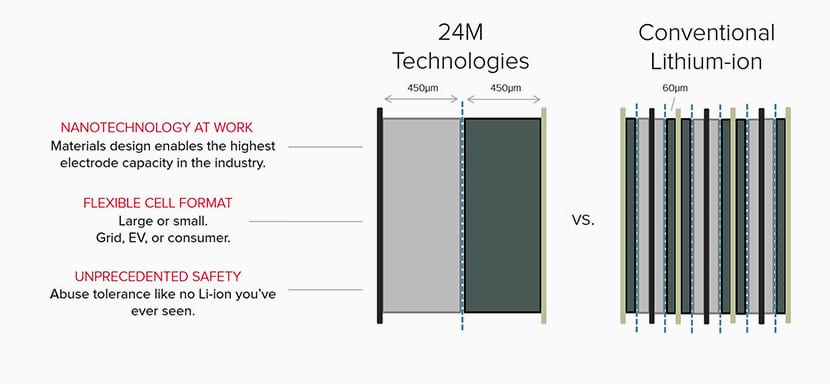

Using the electrolyte as the processing solvent in a binderless system, the SemiSolid platform allows the fabrication of electrodes 4-5 times thicker than conventional processes. The use of thick electrodes greatly decreases the amount of inactive materials content such as copper, aluminum, and a separator, thereby yielding tangible cost savings.

24M SemiSolid Li-ion battery technology compared to convention li-ion battery technology (Click on image to enlarge)

24M SemiSolid Li-ion battery technology compared to convention li-ion battery technology (Click on image to enlarge)

Furthermore, using the electrolyte as the processing solvent leads to the elimination of many capital- and energy-intensive steps such as electrolyte filling, solvent recovery, drying, and calendaring. The elimination of these production steps, and the reduction in plant footprint associated with the steps, leads to a capital expenditure of 30% to 50% reduction compared to conventional lithium ion batteries.

You may also like: PolyCharge Increases the Energy Density and Operating Temp. of DC-Link Capacitors

In connection with the thick-electrode-driven architecture bill of materials advantage, the reduced capital cost structure contributes to what 24M describes as an industry-leading cost of goods.

24M says that the fabrication process for its batteries use one-fifth the factory space of traditional lithium-ion batteries. Moreover, the company says that the production process makes extensive use of commercial, off-the-shelf components.

According to 24M, its batteries can be produced for low cost without giant factories, and production can be scaled with "Copy Exact" module plants. Unlike conventional lithium-ion battery manufacturing, the 24M process does not use organ solids, and 24M says that its battery technology is the most recyclable li-ion batteries ever.

"Kyocera considers the unique 24M SemiSolid approach the emerging standard for lithium-ion battery manufacturing," said Masahiro Inagaki, Senior Executive Officer at Kyocera. "The ability to cost-effectively manufacture advanced lithium-ion batteries can enable Kyocera to expand residential sales throughout Japan."

Kyocera supplies solar power generating systems, automotive and industrial components, semiconductor packages, electronic devices, copiers, printers, and mobile phones with annual sales of $14.6 billion.

"Kyocera is a long-time investor and supportive partner of 24M and we look forward to realizing our shared vision for cost-effective lithium-ion battery manufacturing," said Naoki Ota, President and CTO of 24M. "Kyocera's plans to use the 24M SemiSolid platform is validation that our low-capital, cost-effective approach is achievable at scale."