Double DPAK Top-Side Cooled SMD Solution for High-Power Applications

Increasing complexity of end products is challenging the design parameters for high power supplies: these require higher power and more efficiency in an even smaller space. Semiconductor devices are essential to the operation and performance of modern switched mode power supplies (SMPS). Over the last years, a trend towards surface mount devices (SMD) has been emerging. Thermal management of the present-day SMD-based SMPS designs still remains a barrier to efficiency.

Infineon Technologies AG offers Double DPAK (DDPAK), the first top-side cooled SMD package, addressing high power applications such as server, telecom, solar and high-end PC power. This new packaging solution enables fast switching and high efficiency in reduced size and weight with a minimized total cost of ownership.

The innovative top-side cooled package exceeds the industry's quality requirements. Thanks to the innovative top-side cooling concept, it further shapes the high power SMPS market. The features of DDPAK get combined with the benefits of the already existing high voltage technologies of 600V CoolMOS™ G7 SJ MOSFET and CoolSiC™ Schottky Diode 650V G6. The thermal decoupling of the printed circuit board and semiconductor enables higher power density or longer system lifetime.

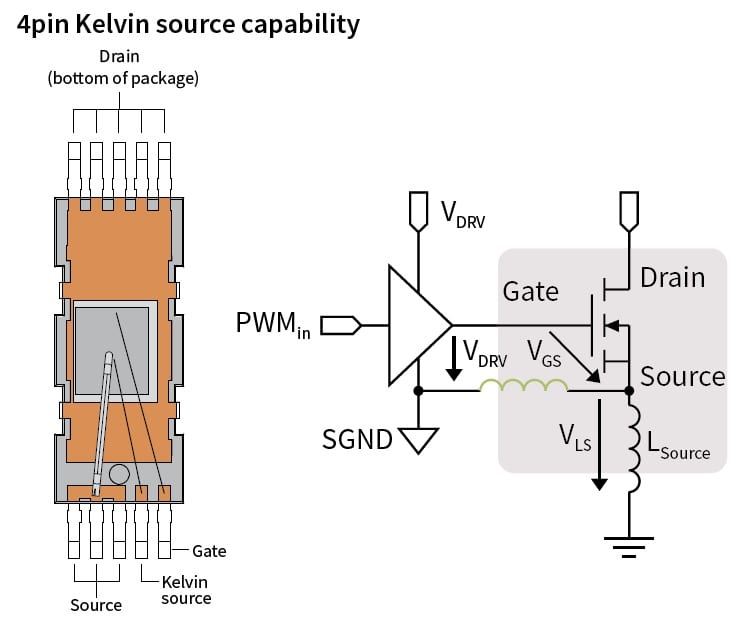

DDPAK offers industry-leading performance as an SMD alternative for high power SMPS designs. Its four-pin configuration allows for separate pin source-sense to deliver undisturbed signal to the driver. Thus, it provides higher efficiency at full load.

Infineon enables optimized system solutions for high power designs by combining its CoolMOS G7 with CoolSiC G6 and EiceDRIVER™ families.

600V CoolMOS G7 SJ MOSFET and CoolSiC Schottky Diode 650V G6 with DDPAK packaging are available now.

Top-side cooling at a glance

SMD based SMPS designs support fast switching and help to reduce the parasitic inductance associated with long leaded packages such as the common TO-220 package. In today's SMD based designs, the output power is restricted by the thermal limit of the PCB material because the heat must be dissipated through the board. Thanks to the top-side cooling concept of DDPAK, the thermal decoupling of board and semiconductor is possible, enabling higher power density or improved system lifetime.

About 20 percent higher power dissipation

DDPAK based SMD solutions allow to reach up to 20 percent higher output power on the board temperature level of a standard cooling concept enabling higher power density at a given form factor.

Around 12°C lower board temperature

DDPAK based SMD solutions allow to drive the application at around 12°C lower board temperature on the output power level of a standard cooling concept leading to increased system lifetime.