alpha-En, Mercedes-Benz, and Princeton Partner on Thin-Film Li-Metal Batteries

alpha-En Corporation, an innovative clean technology company that has developed a patent pending process to produce high purity thin-film lithium metal anodes and associated products at room temperature, announced today the commencement of a joint research program with Mercedes-Benz Research and Development North America and Princeton University.

This joint research program's investigation of alpha-En's pure lithium metal thin films in advanced battery systems will be conducted at Princeton University under the direction of Daniel Steingart, Associate Professor of Mechanical and Aerospace Engineering at the Andlinger Center for Energy and the Environment.

The purpose of this program is for all parties to work together using alpha-En's highly pure lithium metal Nano-rods to investigate the potential of certain next-generation battery technologies with the purpose of improving cell performance and battery production for electric vehicle and consumer product applications.

Jerome I. Feldman, CFO, Chairman of the Board, alpha-En Corp.

Jerome I. Feldman, CFO, Chairman of the Board, alpha-En Corp.

"We are very pleased and proud to be part of this joint research program with one of the world's leading luxury automobile manufacturers at one of the most preeminent University and research institutions in the world," said alpha-En Founder and Executive Chairman Jerome Feldman. "Lithium metal batteries have long been considered the Holy Grail of energy storage."

"As a developing materials company, we are fortunate to be able to leverage the expertise of leading electrochemical researchers in industry as well as academia. It is a pleasure to expand our existing relationship with Daniel Steingart and Princeton to include Mercedes-Benz, creating this unique research group," said Emilie Bodoin, alpha-En's Managing Director of Business Development.

alpha-En has developed the first process for the production of Lithium Metal using clean technology. Now the demand for Lithium Metal can be met without harming the environment.

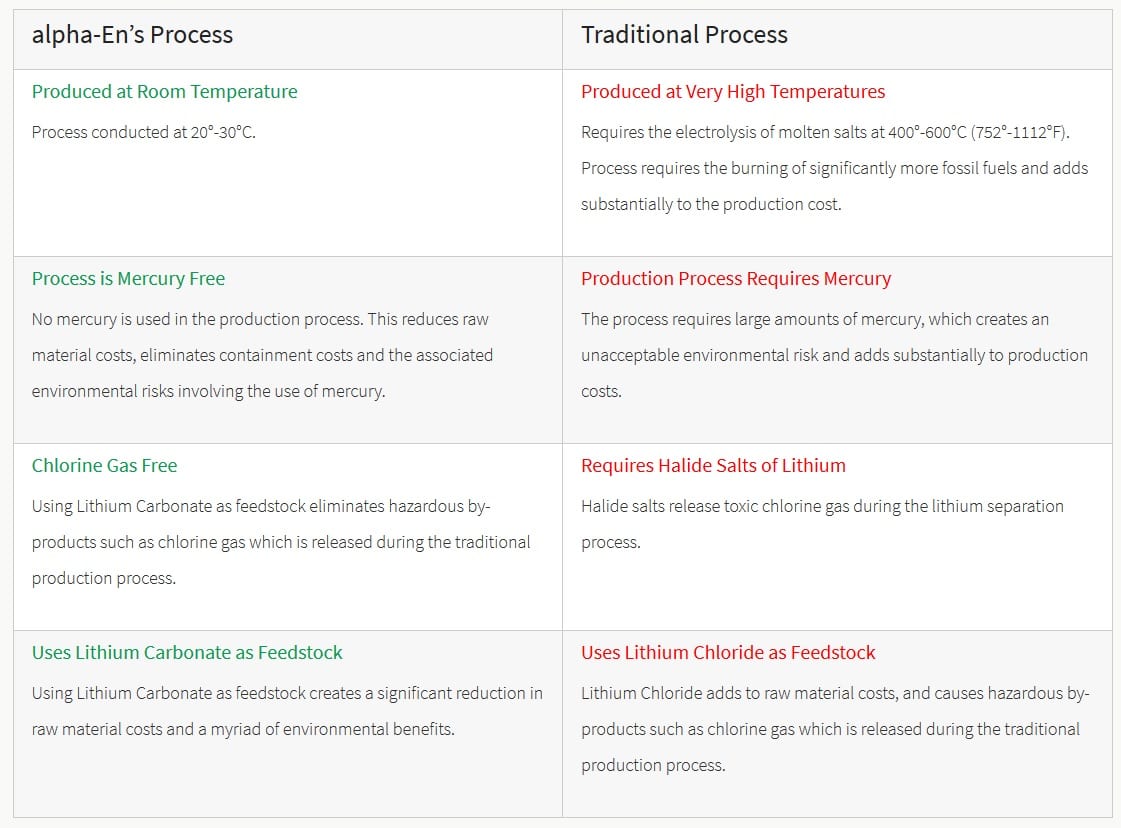

Reducing raw material costs is the key to profitability for battery companies. Alpha-En's novel process allows for production of Lithium Metal at a significant cost savings. The benefits of our process are noteworthy:

- Using Lithium Carbonate as feedstock reduces raw material costs.

- This room temperature process requires minimal electricity.

- The process does not require mercury, again reducing raw material costs and eliminating containment costs.

- The process does not release toxic chlorine gas, eliminating containment costs and associated environmental hazards.

- This proprietary technology and the absence of many chemicals normally required yields an extremely pure product: lithium metal without nonconductive impurities.