Würth Elektronik and Infineon Technologies AG are jointly offering a complete and ready-to-use 200W wireless power system. With this kit engineers can discover the advantages of this technology for themselves and easily integrate it into product designs.

Applications are expected to include: Drones, robotic lawn mowers and power tools; Industry 4.0 and IoT; Industrial applications; Devices in a medical environment; and Devices with a large number of mating cycles to avoid connector damage.

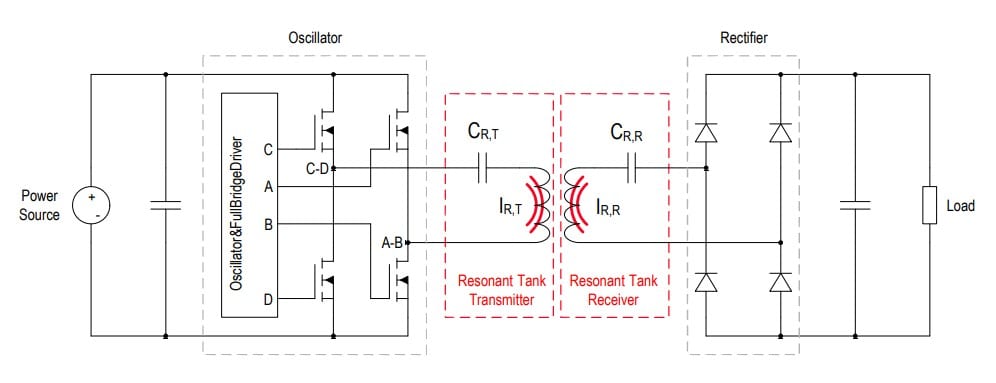

This development kit is based on a full-bridge resonance converter. This circuit is not self-oscillating; the switching frequency is determined by the oscillator and is tuned to the resonant frequency of the series resonant circuit.

The circuit diagram (below) can be divided into the following sections: Oscillator with fixed duty cycle (50%) and full-bridge MOSFET driver; Full bridge of 4 switching elements (MOSFETs); Series resonant circuit consisting of resonance capacitor and WPT transmitter coil; Series resonant circuit consisting of resonance capacitor and WPT receiver coil; and Rectifier (bridge rectifier or synchronous rectifier).

Block diagram of a full bridge resonance converter (click on image to enlarge)

Block diagram of a full bridge resonance converter (click on image to enlarge)

The flow of current in the resonance circuit is sinusoidal and a phase shift between the voltage signals and the current signal occurs. This phase shift occurs because the switching frequency of the full bridge is above the resonant frequency of the series resonant circuit. The operating point is located in the inductive range of the series resonant circuit; the current will follow the voltage.

This is very important for operation, as only through this phase shift to the inductive range is ZVS (zero voltage switching) operation possible. This gives the highest efficiency. If the phase shift goes into the capacitive range, i.e. the current precedes the voltage, the converter is no longer working in ZVS mode, but ZCS mode (zero-current switching). ZCS operation leads to higher losses because the current commutates hard into the body diodes of the MOSFETs. In unfavorable circumstances, this can destroy the MOSFETs

Advantages of this concept:

- Scalability from low power to very high power (10W to several 10kW)

- The current flow in the resonance circuit and rectifier is sinusoidal, good EMC behavior

- The MOSFETs switches at zero voltage, giving very high efficiency >90%

- Easily scalable for many different voltages / currents

- By changing the switching frequency, the output voltage can be higher or lower than the input voltage

- Output voltage can be regulated

- Data can be transmitted between receiver and transmitter

200W wireless power development kit

200W wireless power development kit

With the ever-increasing spread of wireless power transfer in consumer electronics, e.g. in smartphones and charging stations, manufacturers of industrial and medical technology are focusing more and more on this technology and its benefits.

This technology offers interesting approaches, especially for industries and areas where harsh working conditions are common, such as construction machinery, explosive atmospheres (ATEX), agriculture, etc. For example, expensive and vulnerable slip rings can be superseded, reducing maintenance and extending the life of the product.

In medical technology, too, contactless energy transfer offers numerous benefits. Special requirements for hygiene and sterility of medical devices apply here, while the devices and systems must also be resistant to harsh cleaning agents and chemicals. Contactless energy transfer eliminates the need for special connectors with (for example) particularly good seals.

Since increasing amounts of data are transmitted wirelessly – e.g. via WiFi, Bluetooth, etc. – transferring the required energy wirelessly as well is a sensible development. The aim of this development kit and associated application note is to show the developer how a proprietary contactless power transmission system rated at several hundred Watts, including data transmission, can be created simply and efficiently.

Key components from Infineon and Würth Elektronik (click on table to enlarge)

Key components from Infineon and Würth Elektronik (click on table to enlarge)

The Wireless Power Kit provides these added values:

- Plug & Play 200W Wireless Power Development Kit, Extended Medium Power Solution

- Complete solution consisting of a transmitter and a receiver board

- Data transfer between receiver and transmitter board

- Manual and automatic output voltage control

- IoT sensor I²C interface

- Flexible and modular approach for fast integration of wireless power in your product design